Filters Super Market

Home » Products » Filters Super Market » Extruder Screens

-

- Graco Type Filters

- Inline Strainer Without Wings

- Wagner Type Filters - Titan

- Graco Type Filters - Plastic

- Graco Type Filters - Plastic Short

- Graco Type Filters - Plastic Mini

- Wagner Type Filters

- VR Type Filters

- Böllhoff Type Filters

- Wiva Type Filters

- Wiwa Type Filters - Mini

- Colora Type Filters

- Binks Filters-II

- Binks Filters - III

- Kremlin Type Filters

- Delon type Filters

- Nordson Type Filters

- Graco Type Filters- mini

- Wagner Type Filters - Puma

- Speeflo Manifold Filter

- Supports Filters

Filters Super Market

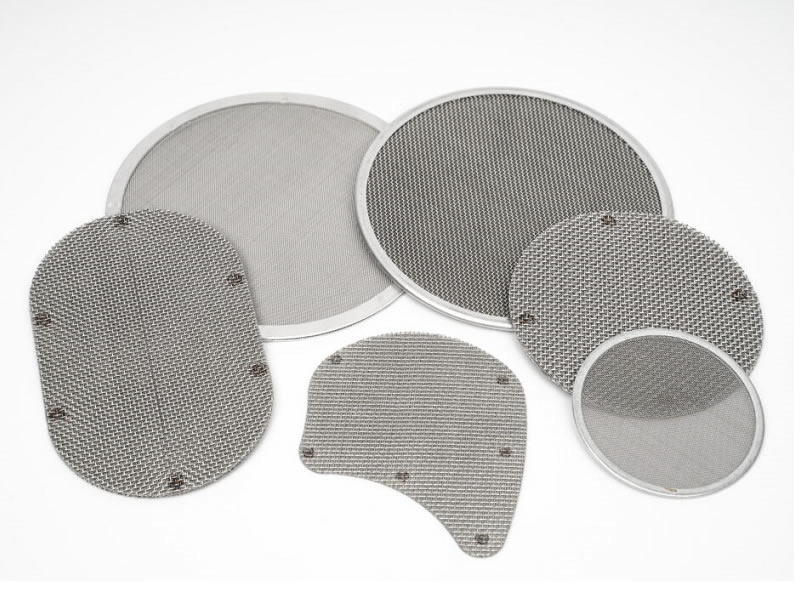

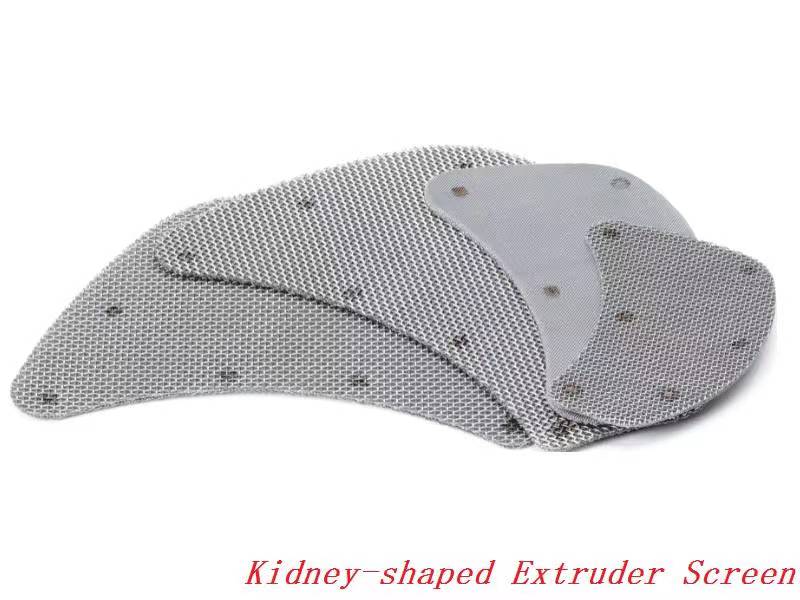

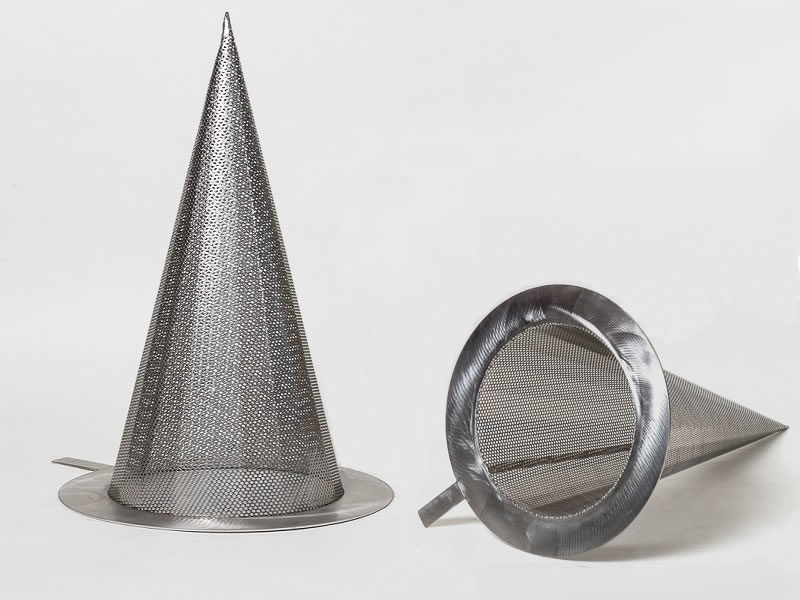

Extruder Screens

Extruder screen is a pack type filter element made of metal wire mesh layers, designed for the melt filtration process. It is used in plastic and rubber processing machinery to ensure a clean and viable extrusion....

Extruder Screens are an imperative part of the melt filtration process. It is used in plastic and rubber processing machinery to ensure a clean and viable extrusion. Our wire cloth screen for extruder filtration available in various materials, weaves all with a wide spectrum of micron ratings to suit different filter use.

Specifications:

Materials: Black wire cloth, SUS304, SUS316, SUS316Lstainless steel wire mesh and brass wire mesh woven Etc.

Shape: Circle,disc,square,oval,rectangular,kidney,cones and other special shape

Edge: Aluminum or non-framed.

Layers: 1–5layers or multiple layers.

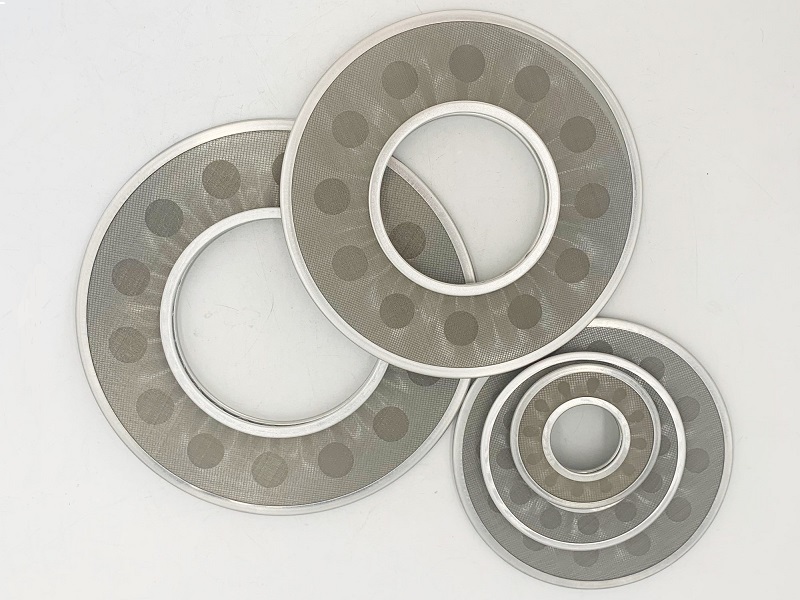

Our wire mesh single screen filters are often used in the plastic reclamation industry, possibly with a Dutch Weave filter used with a plain weave support filter.

These are also used in the extruded profiles and blown film industries where the contamination of the raw material is less and there is often lower pressure within the extruder head.

JD spot welded wire mesh filter packs are excellent in any field where a specific graduation filtration is required.

Another advantage is that it stops single screen filters being placed into the extruder incorrectly. For example a pack consisting of three meshes could consist of a 10mesh / 20mesh / 10mesh; meaning that whichever way the wire mesh filter is placed into the extruder head, it will work correctly.

JD wire mesh filter rim packs feature spot-welded packs with an Aluminium or Stainless Steel rim added for extra rigidity and strength.

These are excellent for use where the extruder screen filter is operating at high pressures or if there is a danger of contamination getting around the edge of the breaker plate.

Features:

With smooth screening surface with no sharp edges, burrs or acute angles.

Available in different size, variants and specifications.

Highly durable with robust structure.

Anti-abrasive & anti-corrosive in nature.

High quality and filtration capacity.

Precise fitting filter elements.

Optimum cost-performance ratio.

Constant quality control during production.

Applications:

Extruder screen is essential in preventing contamination in the melted mass during the extrusion process. It is effect to keeps away mixing of foreign particles in finally equipped extrusion product and provide a clean and clear extrusion to use. Mainly used for filtration of plastics and rubber processing industry, chemical and pharmaceutical industry.

| Standard Extruder Screen 10*10 to 500*500 | |||

|---|---|---|---|

| Mesh | Wire Dia. mm | Aperture Size mm | Open Area |

| 10×10 | 0.711 | 1.829 mm | 51.8 |

| 14×14 | 0.457 | 1.357 mm | 55.9 |

| 16×16 | 0.457 | 1.131 mm | 50.7 |

| 20×20 | 0.559 | 0.711 mm | 31.4 |

| 20×20 | 0.457 | 0.813 mm | 41.0 |

| 24×24 | 0.376 | 0.682 mm | 41.4 |

| 30×30 | 0.376 | 0.531 mm | 34.2 |

| 30×30 | 0.310 | 0.536 mm | 40.0 |

| 40×40 | 0.274 | 0.361 mm | 32.3 |

| 50×50 | 0.193 | 0.335 mm | 43.6 |

| 60×60 | 0.193 | 0.230 mm | 29.8 |

| 80×80 | 0.122 | 0.196 mm | 37.9 |

| 100×100 | 0.102 | 0.152 mm | 36.0 |

| 120×120 | 0.091 | 0.120 mm | 31.8 |

| 150×150 | 0.071 | 0.088 mm | 29.6 |

| 200×200 | 0.050 | 0.077 mm | 36.76 |

| 250×250 | 0.040 | 0.062 mm | 36.76 |

| 300×300 | 0.040 | 0.045 mm | 27.83 |

| 325×325 | 0.035 | 0.043 mm | 30.49 |

| 400×400 | 0.028 | 0.036 mm | 31.25 |

| 500×500 | 0.025 | 0.026 mm | 25.79 |