Filter Tube Mesh

Home » Products » Filter Tube Mesh » Custom Metal Filters

-

- Graco Type Filters

- Inline Strainer Without Wings

- Wagner Type Filters - Titan

- Graco Type Filters - Plastic

- Graco Type Filters - Plastic Short

- Graco Type Filters - Plastic Mini

- Wagner Type Filters

- VR Type Filters

- Böllhoff Type Filters

- Wiva Type Filters

- Wiwa Type Filters - Mini

- Colora Type Filters

- Binks Filters-II

- Binks Filters - III

- Kremlin Type Filters

- Delon type Filters

- Nordson Type Filters

- Graco Type Filters- mini

- Wagner Type Filters - Puma

- Speeflo Manifold Filter

- Supports Filters

Filter Tube Mesh

Custom Metal Filters

Ceramic Fiber Square Rope is braided by ceramic fiber yarns,it is used as heat insulating materials and an excellent substitute for asbestos packing....

Metal filters are used primarily in commercial and industrial/OEM applications. In some applications the goal is to protect downstream components from particulate matter. In other cases, a metal filter can be used to separate, or screen one substance from another. Whether your specific application calls for removing unwanted contaminants from fluid or air, protecting expensive process equipment, or simply separating one material from another, JD Hardware can manufacture a custom metal filter for your exact specifications from wire cloth, perforated metal, or expanded metal. Custom fabricated metal filters can deliver the perfect size dimensions and performance characteristics desired.

Metal Filter Materials

Wire cloth filters, expanded metal filters, and perforated metal filters can be designed and manufactured using a wide range of materials:

Stainless Steel 304, 304L, 316, 316L, 347, Monel, Aluminum, Carbon Steel, Galvanized Steel, Copper, Brass, Bronze.

In some applications, filter design requires a mix of materials for support or to develop a protective underlying or outer structure of expanded or perforated metal or a coarser mesh that guards delicate pleated interior components.

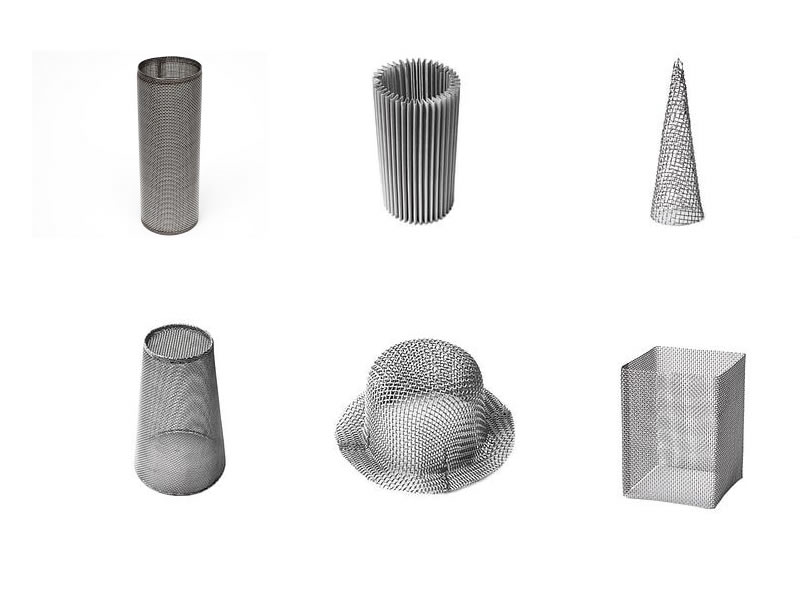

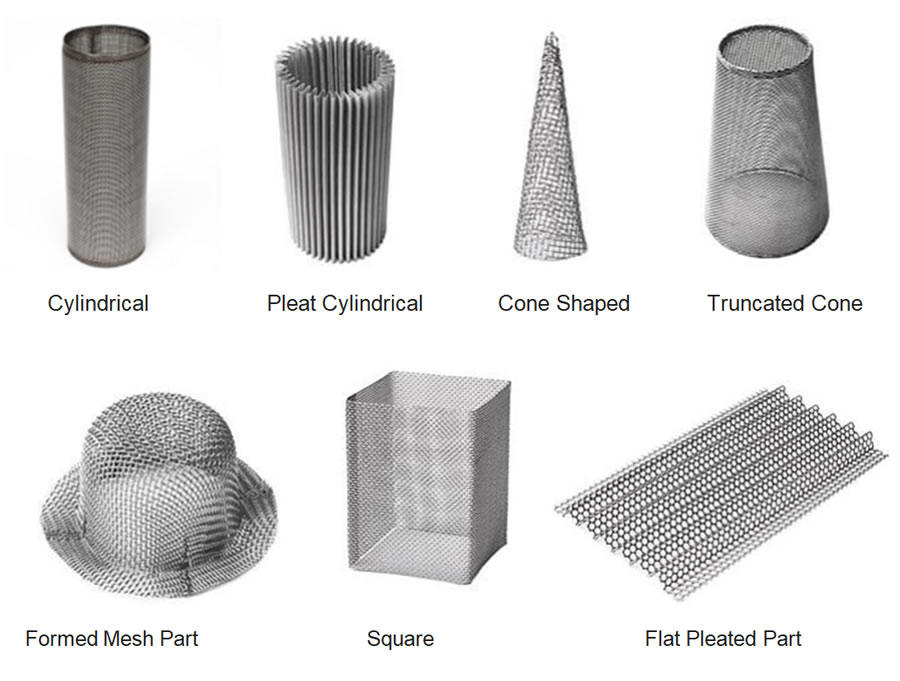

Typical Metal Filter Shapes, Closures & End Styles

Metal filters can be formed using a variety of techniques. The specifics of your filtration requirement – particles size, GPM flow rate, contact liquid as well as the physical space limitations into which the filter must fit, all affect the construction type and the filter end formation.

Filter and Strainer Types:

End Closure Types:

Design Assistance

Our team will work with your engineers to provide metal filter design assistance or help develop prototypes for any style of metal filtration device imaginable. We have helped turn thousands of ideas into working metal strainer filters, strainers and screens for a wide range of industries. JD utilizes a collaborative process where our team interacts with your engineering staff every step of the way. Those steps

include:

Carefully reviewing your drawings and material selections.

Recommending design or material options that deliver better performance and the most cost-effective finished product possible.

Advantages of Metal Filters

Metal filters are excellent for use in applications that will include continuous exposure to liquid or moisture, or where paper filters do not offer sufficient rigidity or strength. In addition to outstanding durability, there are other inherent design benefits available with metallic filters. Metal filters can be fabricated by welding and crimping, eliminating the need for adhesives or epoxy bonding. Unlike paper filters, metallic filters can withstand temperature range in excess of 500° F and can withstand extremely high differential pressures. Depending upon metals used, your filter can be compatible with most caustic fluids. Stainless steel filters, for example, offer a high degree of resistance to corrosion in caustic environments. Best of all, metal filters are inherently cleanable and reusable. Reusable metal filters offer superior service life when compared to paper and cloth filters, and are commonly used in metal cutting, engine and compressor oil, and wastewater applications.

Our media is especially suited for the following applications:

Filters for High Temp Applications

High Pressure Filtration

Filters for Highly Corrosive Applications

Erosion Resistant Filters

Filters that can be cleaned and re-used

Send us a drawing, photo or sample. We are happy to propose options to solve your filtration needs.